over the last forty years, our experienced crews have installed tens of thousands of metres of piling to meet the needs of industrial or domestic clients

PILING

FOR LARGER PROJECTS WHERE ACCESS IS NOT RESTRICTED AND LOW VIBRATION IS STILL A REQUIREMENT, WE HAVE RIGS THAT CAN INSTALL PILES UP TO 273MM DIAMETER, PROVIDING 450KN SWL IN MOST GROUND CONDITIONS WITH MINIMAL SITE PREPARATION AND NO SPOIL CREATED DURING INSTALLATION

WHY USE LARSEN FOUNDATIONS?

Competitively priced & efficient installation of mini piles throughout the UK and Ireland by fully certified Piling Operatives to latest codes and standards

Conveniently based - Belfast and Dublin

Minimum access required from 600mm wide

Low vibration solutions

Fast and efficient service

Full complement of rigs for most situations

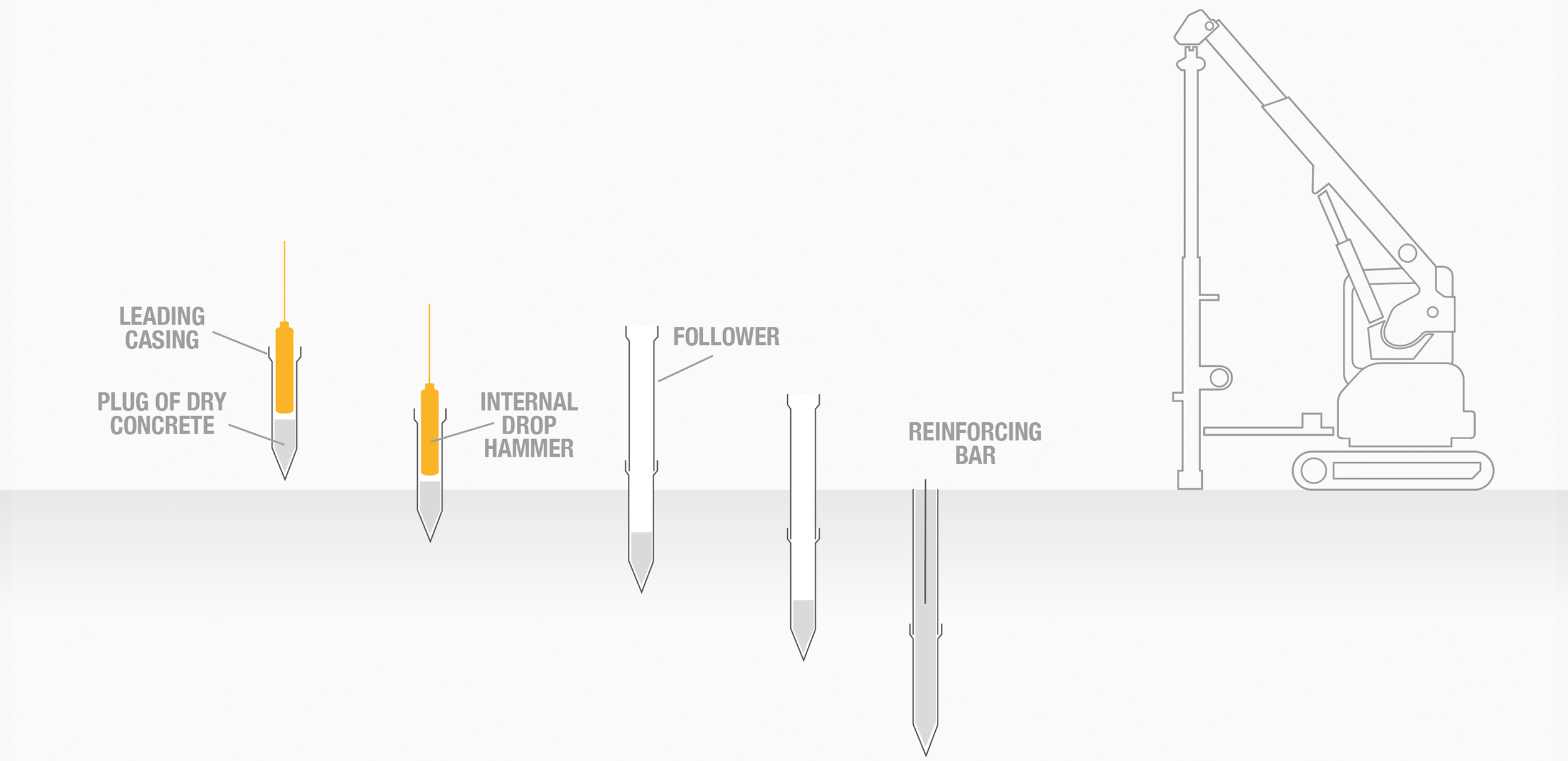

MINI PILING

FOR RESTRICTED ACCESS SCENARIOS, WE HAVE MINI PILING RIGS RANGING FROM HAND HELD TO 5 TONNE. OVER A RANGE OF PILE DIAMETERS, WE CAN INSTALL PILES IN AS LITTLE HEADROOM AS 2.2M FOR PILE SAFE WORKING LOADS BETWEEN 50-300KN.

WHY MINI PILE?

Mini piling is a proven system to address foundation problems. For example:

Unsuitable ground conditions for standard foundations

Risk of undermining or damaging existing services and/or foundations

Restricted access for piling equipment

Minimise costs by reducing the depth of the hardcore base required for the mini piling rig

Can operate in a low headroom situation

Eliminates fumes in confined areas, if using an electric power pack

A low vibration solution

Minimal noise levels

Upgrading foundations / floors for increased loadings - mini piles are a less expensive option

No spoil created by use of mini piles

Minimal disruption to the site or building

underpinning & structural repair

WE ARE THE LARGEST UNDERPINNING CONTRACTOR IN IRELAND, RESPONSIBLE FOR STABILISING STRUCTURES RANGING IN SIZE FROM THE LARGEST BUILDING EVER UNDERPINNED IN IRELAND, THROUGH TO THE CORNER OF A DOMESTIC GARAGE.

WE OFFER A FULL DESIGN & INSTALL UNDERPINNING PACKAGE TO NHBC, HOMEBOND, INSURANCE COMPANIES, HOME OWNERS AND MAIN CONTRACTORS. WITH MEMBERSHIP OF ASUC (ASSOCIATION OF SPECIALIST UNDERPINNING CONTRACTORS) WE CAN PROVIDE 12 YEAR INSURANCE GUARANTEES ON OUR UNDERPINNING REPAIRS.

IN CONJUNCTION WITH OUR UNDERPINNING SYSTEMS OR FOR STANDALONE CRACK REPAIRS, WE OFFER A FULL RANGE OF CRACK REPAIR SOUTIONS.

Piled underpinning may be necessary for a variety of reasons.

Underpinning may be defined as the process of strengthening and stabilising the foundation of an existing building or structure. Underpinning may be necessary for a variety of reasons, the most common of which are:

The existing foundation is not strong or stable enough

The construction of nearby structures necessitates the excavation of soil supporting existing foundations

The usage of the structure has changed

The properties of the soil supporting the foundation may have changed or may have been mischaracterised during planning / construction

The oldest and most well known form of underpinning is ‘Traditional Underpinning’. Traditional Underpinning stabilises the existing walls by excavating beneath the existing foundations in a ‘Hit & Miss’ fashion to a depth where firm load bearing strata exists. The excavated material is replaced with mass concrete and can be reinforced or un-reinforced depending on the application.

Traditional Underpinning is usually applied when the existing foundations are at a shallow depth. It is economical if load bearing strata can be found at a depth up to 1.5m. If load bearing strata is found to be at a depth greater than 1.5m then a minipiled solution will be more economical, safer, less obtrusive and faster.

Due to advances in minipiling installation and minipiled underpinning techniques traditional underpinning has become less common and is generally only used to increase the ceiling height of an existing basement.

Larsen Foundations Ltd has several cost effective minipiled underpinning solutions. We can provide a full surveying and underpinning design service. Our most popular restricted access minipiled underpinning solutions are outlined below.

sIMPLY SUPPORTED needleS

This method supports the wall / foundations by installing piles at either side of an existing wall (internally & externally) or at either side of a corner (both piles externally).

A pocket is created either in the masonry above the foundation (if site dimensions allow) or beneath the foundation (if the depth from ground level to top of foundation is shallow – less than 400mm). A cage of structural steelwork is inserted through the pocket and placed over the piles. The needle is then cast in-situ using high strength concrete.

ADVANTAGES OF SIMPLY SUPPORTED NEEDLES

Considerably less excavation than for a traditional underpinning solution thus a reduction in material to be taken off site.

High load capacities possible depending on the diameter of the piles installed and the spacing of the needle beams.

Suitable for restricted access situations.

Quicker than traditional underpinning. The needles are spaced at intervals and there is no requirement for a ‘hit & miss’ approach.

Depending on the wall’s condition, the needles can be at up to 1200mm centres, this reduces site time, plant and labour costs.

CANTILEVER needleS

The construction of the cantilever needle beam is as per the simply supported needle beam. It varies however as both piles are installed either externally or internally (usually externally). The pile installed closest to the wall is a compression pile and the pile furthest away from the building is a tension pile.

ADVANTAGES OF CANTILEVER NEEDLES

Considerably less excavation than for a traditional underpinning solution thus a reduction in material to be taken off site.

Quicker than traditional underpinning. The needles are spaced at intervals and there is no requirement for a ‘hit & miss’ approach.

Suitable for restricted access situations.

Depending on the wall’s condition the needles can be at up to 1200mm centres, this reduces site time, plant and labour costs.

The cantilever needle can be created externally allowing the owner to remain in the property whilst works are being carried out.

sINGLE pile needleS

A single pile cantilever needle beam is a shorter version of the cantilever needle beam that relies on the tension capacity of one pile. It can be installed either internally or externally (usually externally) within a space of 750mm from the wall to be underpinned (including rig access).

ADVANTAGES OF SINGLE PILE NEEDLES

Considerably less excavation than for a traditional underpinning solution thus a reduction in material to be taken off site.

Quicker than traditional underpinning. The needles are spaced at intervals and there is no requirement for a ‘hit & miss’ approach.

Depending on the wall’s condition, the needles can be at up to 1200mm centres, this reduces site time, plant and labour costs.

The single pile cantilever needle can be created externally allowing the owner to remain in the property whilst works are being carried out.

The single pile cantilever needle can be constructed within a space of 750mm making it ideal for highly restricted access situations.

internal piled raft

This underpinning method supports existing walls to individual rooms or entire buildings. Minipiles are installed internally using low vibration piling equipment and the piles are incorporated into a series of needles which are in turn incorporated into a new reinforced concrete structural floor slab. The needle beams project from the raft slab at intervals into the internal and external load bearing walls below ground level.

Depending on the height of finished floor level in relation to finished ground level we can offer a dropped edge raft solution that ensures the ends of the needles are not visible from outside.

For highly loaded structures the spans between the needles are reduced and the needle reinforcement increased. Multi storey buildings of solid masonry construction can be underpinned up to 6 storeys high.

ADVANTAGES OF INTERNAL PILED RAFT

The system provides a new floor slab upon completion of the underpinning works.

The system is carried out from the inside only and removes the requirement to cause disruption to external paths, gardens, drainage etc.

High load carrying capacity.

Where the property to be underpinned has suspended timber floor construction, a minimum amount of excavation may only be required thus reducing construction time.

Timber floors can be replaced with solid concrete floors which can be left at a reduced level to facilitate the installation of insulation or the provision of an underfloor heating system.

HOUSE EXTENSIONS

Whether faced with poor ground conditions or extending a property that has piled foundations, we can help

Combining hand held piling systems with offsite reinforcement fabrication we ensure that your extension is completed quickly and with minimum disruption.

Works can be completed to your engineer’s specifications or we can offer a full design and construct package based on your architectural drawings.